Search This Supplers Products:steel struturewire rodprepainted galvanized coilcontainer househot rolled steel plate/striproof roll forming machine

PPGI PPGL

sourceJUNNAN NEWS

publisherGloria

time2025/08/14

- PPGI/PPGL is a type of coated steel. The surface can be treated through painting, powder coating, or electroplating.

PPGI/PPGL

PPGL stands for Pre-Painted Galvalume Steel Coil. Similar to PPGI steel coil, this material is produced by galvanizing steel and then coating the surface with a layer of paint. This material has better corrosion resistance than ordinary galvanized steel, and due to its durability and aesthetics, it is commonly used in construction, roofing, and other applications.

Therefore, in harsh environments with high salt concentrations, people often choose PPGL.

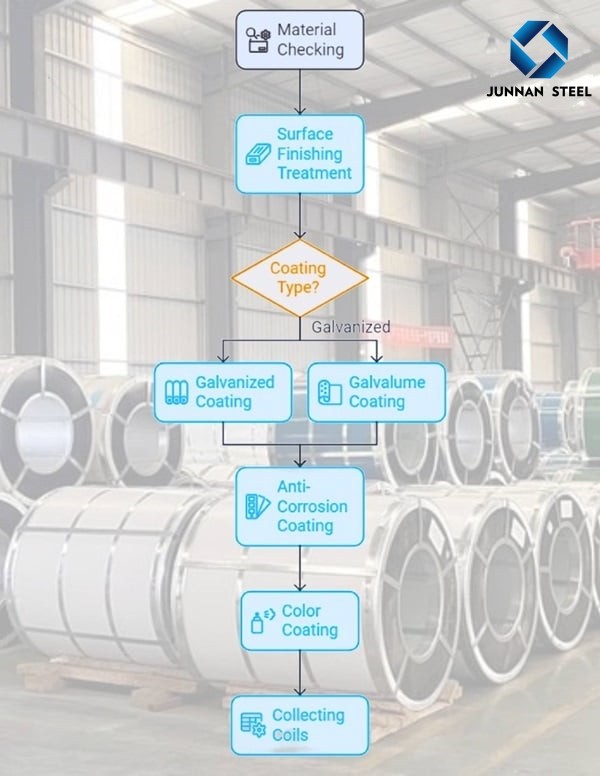

Basic steps in PPGI/PPGL production process

The production process of PPGI/PPGL is quite complex, involving numerous steps. Next, let's take a look at the production process of PPGI/PPGL in MRS Steel. The production process of PPGI and PPGL includes the following steps:

Material inspection: Raw materials undergo careful inspection before entering the production process.

Surface treatment: Steel needs to be cleaned to remove impurities and dirt, which is an important step to ensure that the coating adheres tightly to the surface of the product.

Galvanized coating or galvalume coating: After surface cleaning, the steel will undergo galvanizing or galvalume coating process. This electroplated layer serves to limit product corrosion, helping to maximize the protection of the product surface.

Anticorrosion coating: After being coated with galvanizing or galvalume, another anticorrosion layer is applied to the surface, usually a paint layer combined with antioxidants.

Color coating: Apply a color coating on the surface of the electroplated and anti-corrosion coating. This process can be completed using roll coating or spray painting methods. Collecting coils: After the color coating is completed, place the steel in a furnace to dry the paint layer, then inspect and collect the coils.

For comprehensive solutions in steel building material, please contact Junnan Steel via email at yy..........com or WhatsApp at (+86) 13780503368 for immediate assistance!