Search This Supplers Products:steel struturewire rodprepainted galvanized coilcontainer househot rolled steel plate/striproof roll forming machine

What is the welding and cutting process for I-beam?

sourceJUNNAN STEEL NEWS

publisherGloria Wong

time2019/11/08

- The below is the introduction of the welding and cutting process of I-beam, I hope to help you !

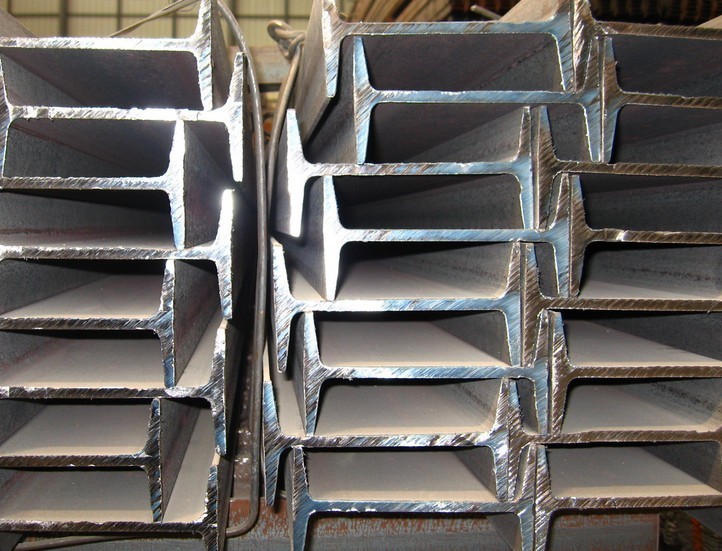

As we all know, I-beam is a type of steel with an I-shape. It is commonly used in the construction industry. The flanges of I-beams are of equal thickness, with rolling sections, and a combined section made of three plates welded. Normal I-beams are all rolled sections, and due to the poor production process, there is a 1:10 slope inside the flange. The rolling of the I-beam is different from the ordinary I-beam. Only one set of horizontal rolls is used. Since the flange is wide and has no slope, a set of vertical rolls must be added while rolling.

Therefore, its rolling process and setting are more complicated than ordinary rolling mills. The maximum rolled H-beam available in China is 800mm high, which is beyond the welded joint section. When the I-beam and the consistent product are being cut and welded, it is important to assign an employee who holds the welder's talent for the construction of the steel structure, and is operating in accordance with the relative specifications of the country's steel construction.

When the I-beam is cut by flame, the web should be cut before the web is cut, and the stress is prevented from becoming cracked. If necessary, the cutting flame should be used to preheat the cutting part before cutting to solve the preheating temperature ≥200 °C.

The cutting edge should be solved in the arc transition. The arc radius is not less than 25mm. After the I-beam is cut, the welding planer should be taken immediately to remove the stress from the cutting part.